- Home

- High Temperature Solutions

- Vitronus

Vitronus

Improve all aspects of your hot glass handling.

tried and tested

High performance materials for glass production

Through innovative material science techniques, Tenmat has developed a product that is ideal for use in hot-end container glass plants. Vitronus is a fibre-reinforced carbide ceramic material that offers up to 5 times longer wear than competing products, meaning less spent on replacement parts and less downtime to change them.

Vitronus at a glance with Vitronus, hot-end container glass plants will be able to:

With Vitronus, hot-end container glass plants will be able to:

-

Improve the

melt-to-pack ratio

- Reduce the consumption of spare parts

- Reduce the number of glass rejects

- Improve efficiency and productivity

Our hot glass handling solution

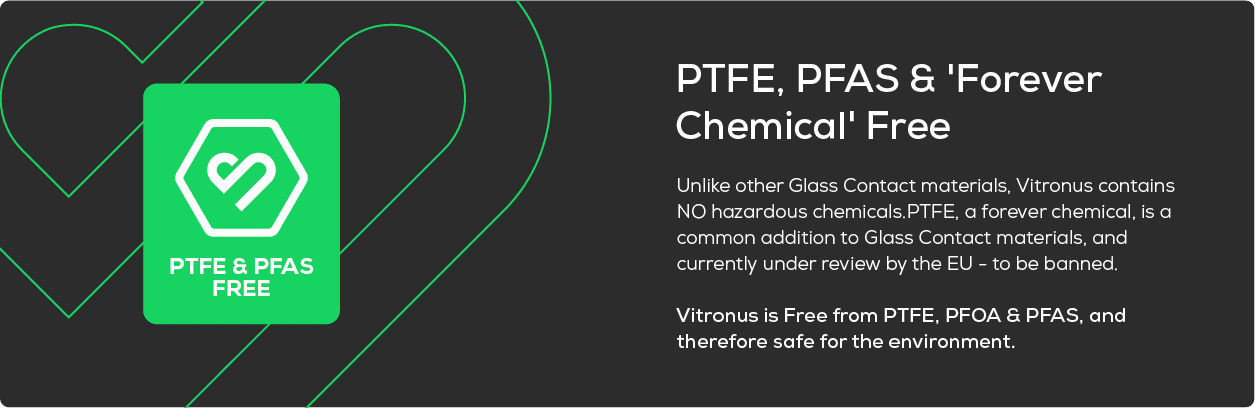

This revolutionary material has insulating properties making it non-porous, tough, smooth, and temperature resistant, which ensures it does not damage the glass during production. Vitronus offers superior performance over alternatives in the following areas:

45x

Reduced oxidisation

With an oxidation rate 45 times lower than a standard CFC.

2.3x

Reduced oil absorption

2.3x less oil absorption than graphite, reducing the risk of thermal contact damage to the glass.

28x

Higher toughness

28x tougher than graphite, reducing the risk of premature breakage.

Vitronus at a glance

We’re revolutionising hot-end container glass plants with our hot glass handling material, Vitronus.

- Long service life

- No thermal marking of glass

- External thermal shock resistance

- No mechanical marking of glass

- High toughness - more reliable

VITRONUS

Hot glass handling

Traditionally, hot-end glass plants have used carbon graphite components although these have numerous pitfalls, such as issues with breakage, a short life span, oxidation and oil absorption. This has led to glass manufacturers looking for materials better suited to their needs – a material to increase efficiency and plant reliability while lowering costs and improving the overall melt-to-pack ratio.

When hot glass containers need transporting to their next destination in the production process, contact with materials can cause damage or distortion to the glass. Vitronus has been designed to overcome shortcomings in incumbent materials to provide a trouble-free operation with minimal glass rejects.

Its benefits of low oil absorption, high-temperature capability, high toughness and high wear resistance whilst still being kind on the glass make Vitronus an ideal choice for contact materials across hot-end production processes.

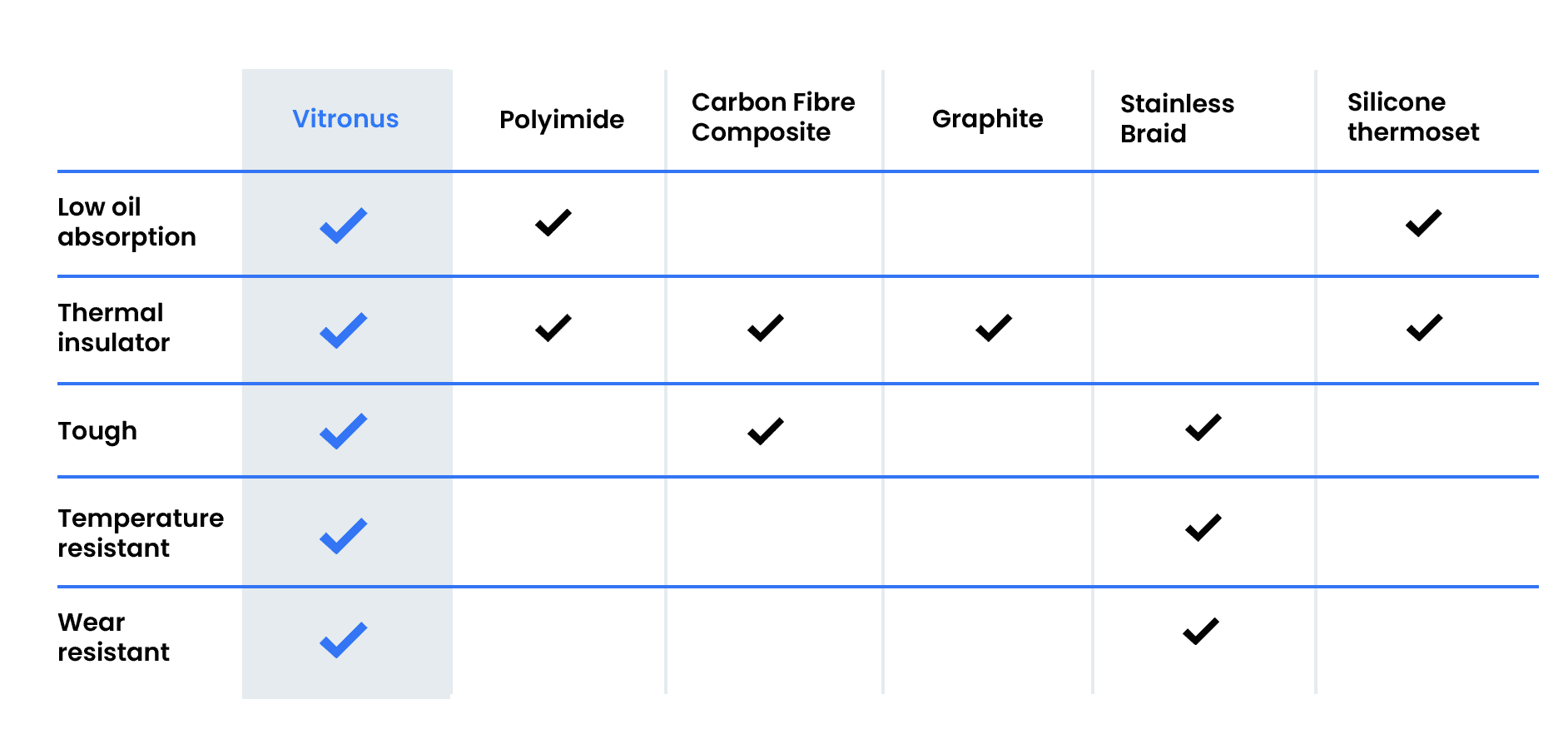

Vitronus v competing materials

The materials involved in glass contact are required to have multiple properties in order to ensure optimum performance. The table shows the key physical properties of a hot-end glass contact material and how Vitronus compares with conventional materials.

VITRONUS

Typical applications

Vitronus can provide a long life and cost-effective operation in the following operations:

- Sweep-out liners/pusher fingers

- Dead plates

- Transfer guide strips

- Transfer fingers

- Stacker bar liners

Please contact our technical sales team to discuss details about your process and issues.