- Home

- High Temperature Solutions

- Metal Production

- Aluminium rollers

High temperature rollers

- Home

- High Temperature Solutions

- Metal Production

- Aluminium rollers

High temperature rollers

METAL PRODUCTION APPLICATIONS

High-Temperature Aluminium Rollers

An extremely tough and resilient material for the aluminium industry. As an expert in the manufacturing of advanced composites, Tenmat Wear developed a unique blend of high-performance fibres to build an extremely tough and resilient material for the aluminium industry.

Feroform F57 is the ideal solution

Feroform F57 is the ideal choice for high-impact applications, providing a long-lasting, maintenance-free wear surface. This innovative material replaces old-fashioned steel rollers, which are infamous for scratching the delicate surface of the aluminium.

- Durability

- No marking of the aluminium

- Longer wear life

- Extreme temperature resistance

- Cost-effective

- Lower change-out frequency

- A trusted choice in aluminum rolling production lines

In modern aluminium hot rolling mills, the quality of rolled aluminium is critical for successful use in applications ranging from aerospace to pharmaceutical. The surface finish of the rolled aluminium is dependent on the rollers. Feroform F57 covered rollers provide a durable, high-temperature-resistant surface that protects the aluminium during the hot rolling process.

Feroform F57 is successfully used by major aluminium manufacturers around the world, eliminating the need for grinding and regular cleaning of the production lines.

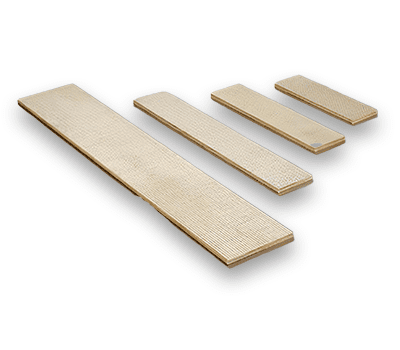

Feroform F57 can be processed around your existing steel rollers. Alternatively, we supply stand-alone full or split sleeves that simply slide onto your steel mandrel. Other applications for Feroform F57 in aluminium plants include sliding pads, bearings, and thrust washers.

Feroform F57

Feroform F57 is a Kevlar-reinforced high-performance material for rotor vanes for compressors and vacuum pumps.

Applications

Application overview

| Application | Material |

| Aluminium Rollers | Feroform F57 |

| Stainless Steel Rollers | Firefly 1125 |