B. C. Wilson, a lime spreading contractor in the UK, has improved the life of the spreader vanes on his Güstrower GDK 6.000K spreader by welding Ferobide to the vanes.

When spreading abrasive products such as steelwork slag, Bruce found the standard hardened steel vanes to wear out in a day.

When spreading abrasive products such as steelwork slag, Bruce found the standard hardened steel vanes to wear out in a day. One row of Ferobide welded to the spreader vanes. The 500 Brinell hard steel wore through in one day, but Ferobide was shown to hold up well.

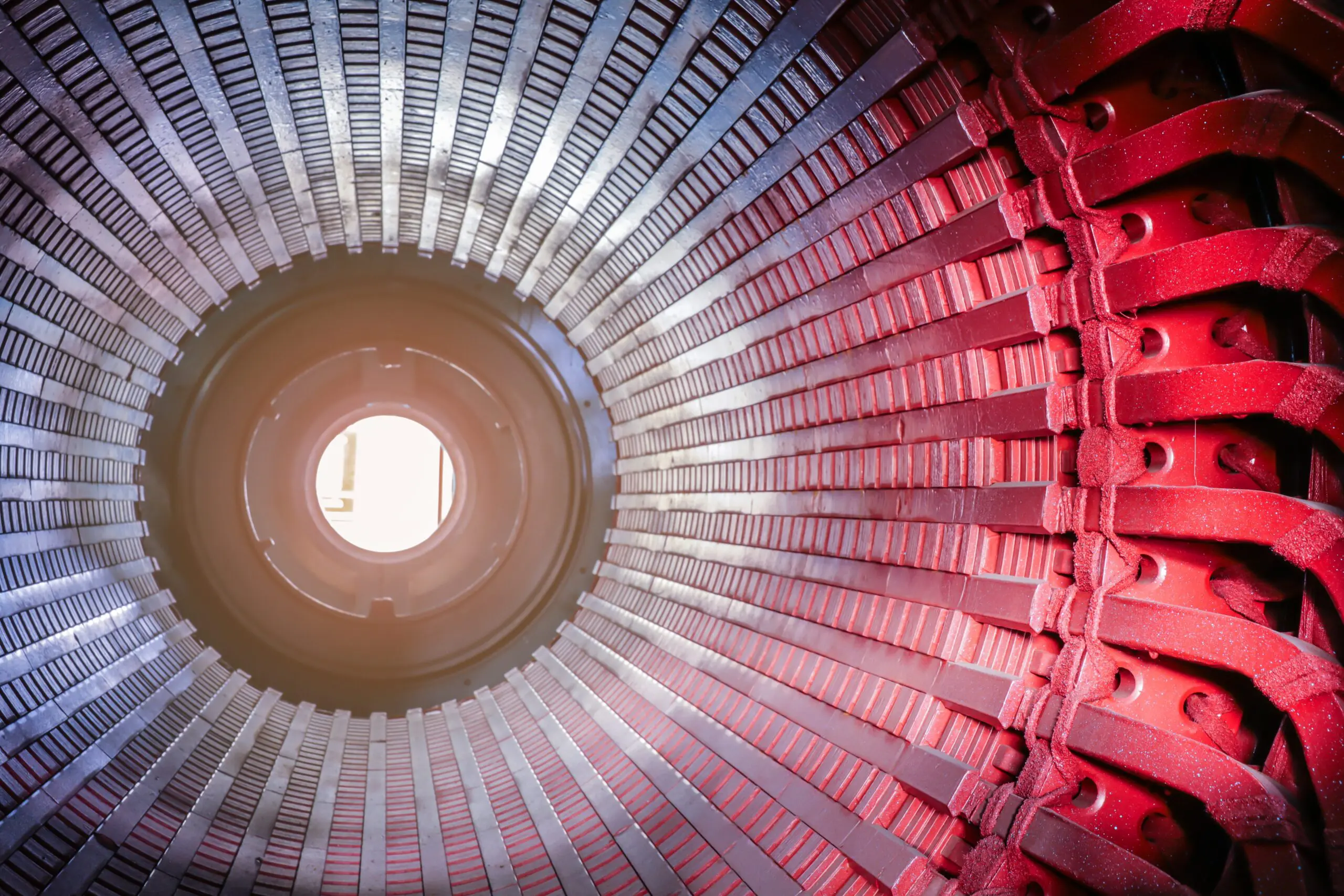

For the second version, three rows of Ferobide was welded onto the vanes and since then they have held up for 10,000 tons of lime and 300 tons of steelwork slag. Three rows of Ferobide welded to the spreader vanes. This photo is taken after one year of use and shows that the Ferobide spreader vane will last a few years.

Spreader disc fitted with Ferobide on the vanes, after a year of use.

For more information, please contact the Ferobide team at ferobide@tenmatwear.com.