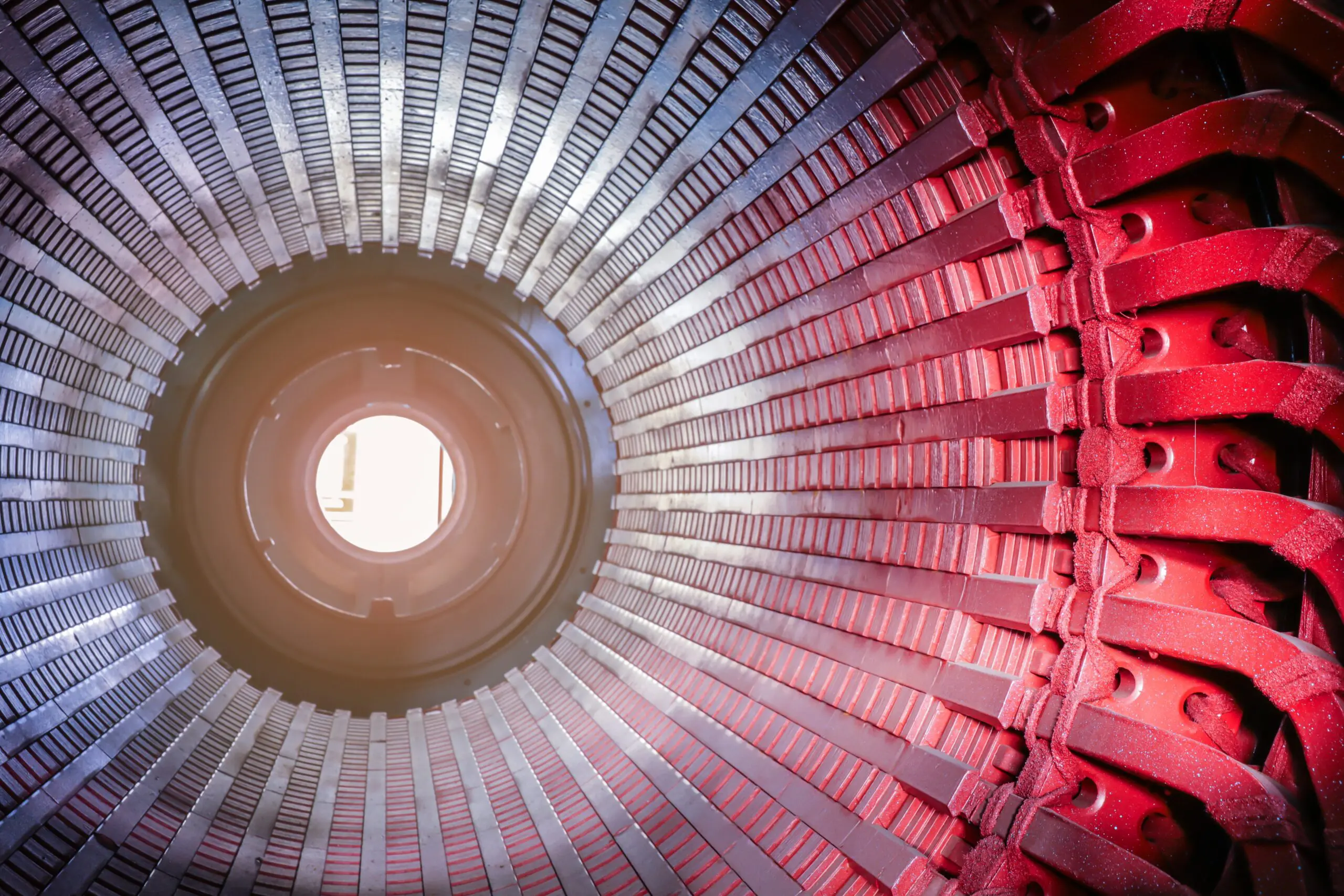

Facing aggressive limestone wear, a Nigerian cement plant turned to Tenmat’s Ferobide liners—and saw over a year of uninterrupted performance.

The Challenge

A major cement plant in Nigeria was grappling with extreme wear and tear on its vertical roller mills due to a highly abrasive grade of limestone. The issue:

-

Frequent unscheduled maintenance

-

Costly production downtime

-

High expenditure on labour and replacement parts

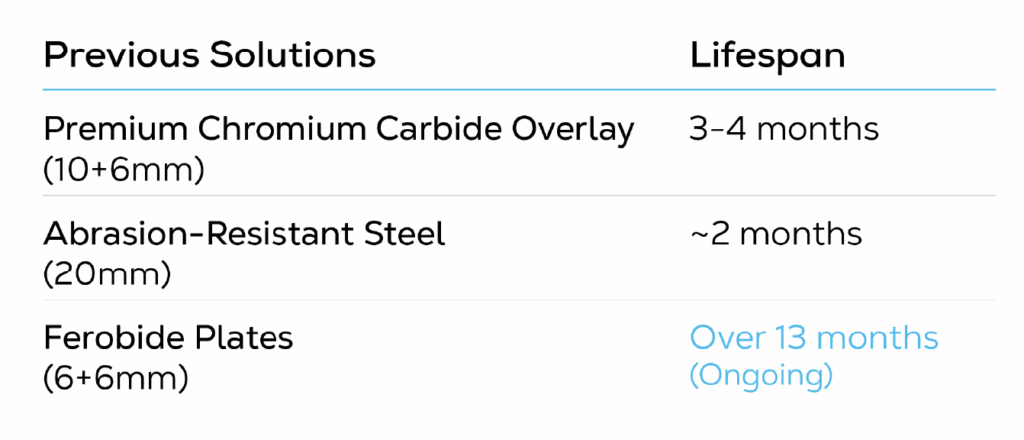

Despite using premium Chromium Carbide Overlay and abrasion-resistant steel, wear liners would only last 2–4 months before needing replacement.

The Solution

In early 2024, Tenmat supplied 1,500 Ferobide wear plates for a trial installation on Production Line 1. Ferobide’s advanced tungsten carbide composite offered superior wear resistance while being easy to install and maintain.

Impact at a glance

Reduced unscheduled maintenance

Lower total cost of ownership

Improved mill uptime and operational efficiency

Comparing solutions

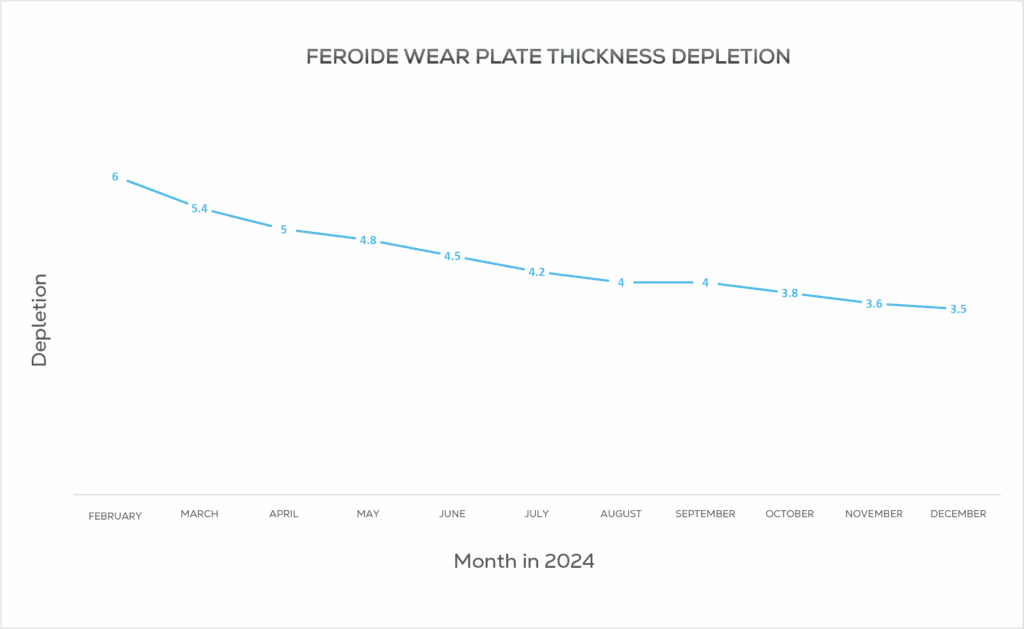

Ferobide significantly outperforms traditional wear liners. While previous materials failed within months, Ferobide maintained low wear rates across the year, supporting continuous high-volume production with minimal maintenance.

What's next?

Following the exceptional performance on Line 1, the plant is preparing to roll out Ferobide liners across all three production lines. The goal is to replicate the durability, cost savings, and uptime improvements across the entire site.

- 1,500 Ferobide plates installed (Feb 2024)

- Supported over 3 million tonnes of production

- Less than 50% wear volume loss recorded

- Outperformed previous solutions in both durability and cost-effectiveness