A highly effective solution

Tenmat, a leading manufacturer of advanced materials and components, has a range of world-renowned composite and polymer materials, including Ferobide, Feroform, Feroglide, Ferosafe and Railko.

Ferobide is a highly effective solution for reducing operating costs in the agricultural, mining and construction sectors.

This tungsten carbide composite is one of the most wear-resistant materials in the world, it is already trusted globally as a reliable solution for minimising equipment downtime. By preventing wear part damage, Ferobide is able to deliver lasting results which minimise equipment downtime and therefore aid in decreasing operating costs.

Ferobide in Farming

Farmers who utilise Ferobide can experience dramatic savings by extending the life of their equipment, reducing the need for frequent replacements and repairs.

For instance, implementing Ferobide has allowed some farms to extend the service life of cultivator wings and legs by several seasons, cutting down metal wear expenses by up to two-thirds. This not only minimises downtime but also boosts overall operational efficiency and profitability.

When used on soil-engaging equipment parts, Ferobide enhances durability against abrasive soil conditions, which can significantly decrease the frequency of part replacements.

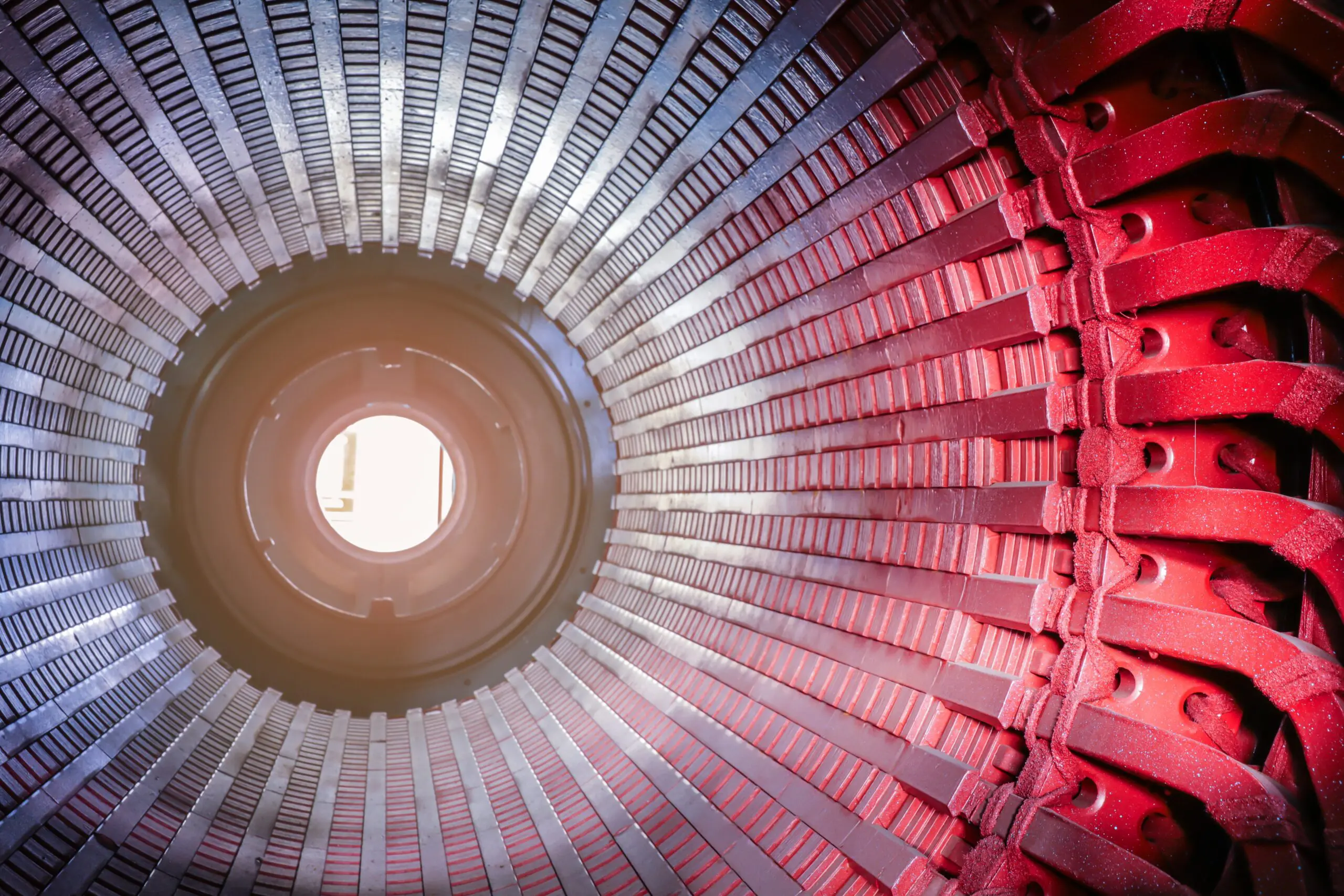

A case study involving sugar cane mills showed that equipment outfitted with Ferobide experienced less wear compared to traditional hard-facing materials, leading to longer operational periods between maintenance shutdowns.

Ferobide in Construction and Mining

Farmers who utilise Ferobide can experience dramatic savings by extending the life of their equipment, reducing the need for frequent replacements and repairs.

For instance, implementing Ferobide has allowed some farms to extend the service life of cultivator wings and legs by several seasons, cutting down metal wear expenses by up to two-thirds. This not only minimises downtime but also boosts overall operational efficiency and profitability.

When used on soil-engaging equipment parts, Ferobide enhances durability against abrasive soil conditions, which can significantly decrease the frequency of part replacements.

A case study involving sugar cane mills showed that equipment outfitted with Ferobide experienced less wear compared to traditional hard-facing materials, leading to longer operational periods between maintenance shutdowns.

The benefits of Ferobide

When used correctly and welded onto suitable surfaces, Ferobide has numerous benefits, which include:

- Significant savings on wearing metal costs

- Increased wear part lifetime

- Reduction in machinery downtime for maintenance

- Increased operational efficiency due to a reduction in downtime

- Quick and easy to weld