Ferobide used in Sweden’s Longest Tunnel

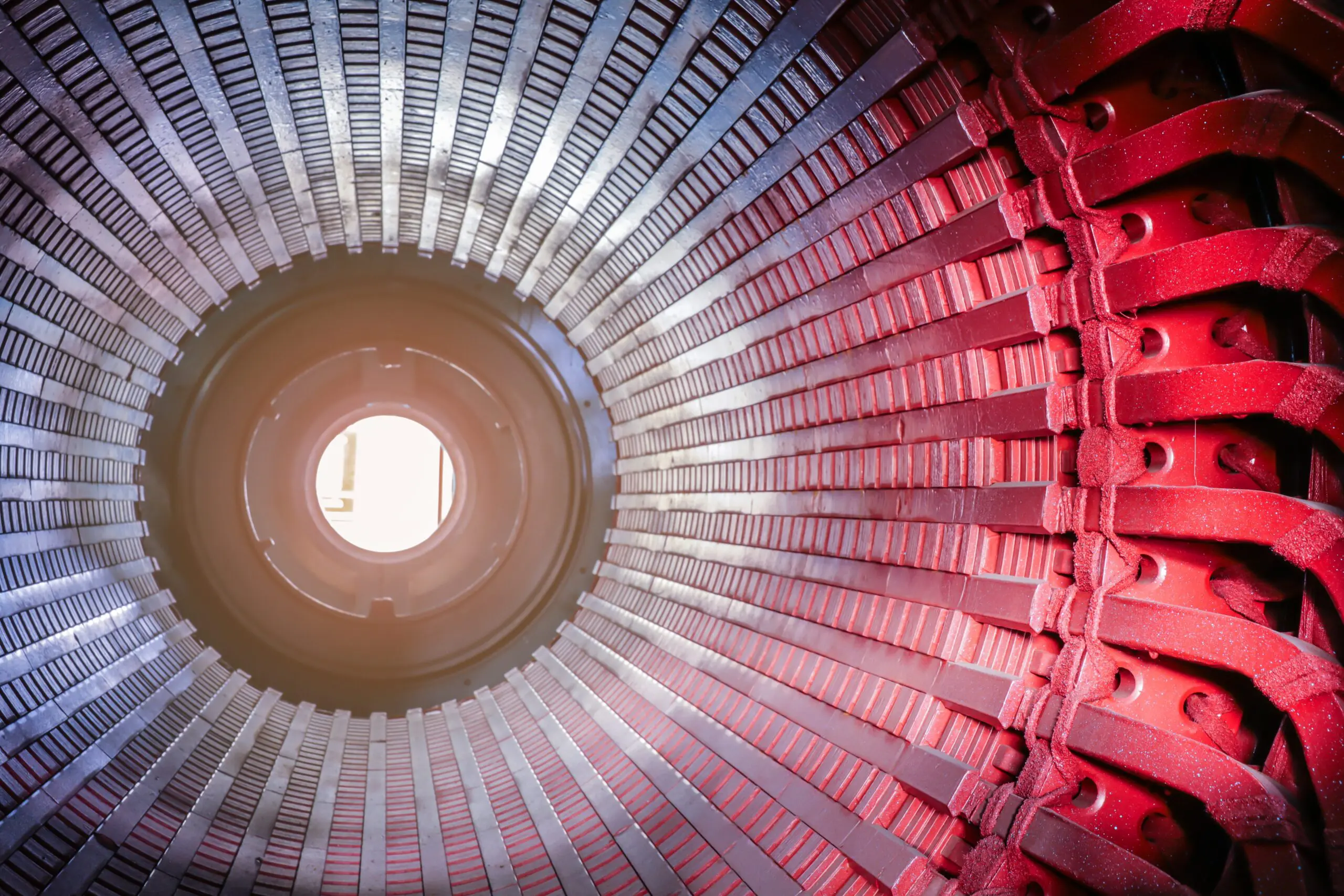

Ferobide has been successfully used on tunnel boring machines (TBMs) to protect areas of the cutterhead in the Swedish Hallandsåsen tunnel project. It presents a long lasting and weldable option to conventional hardened steels and hardfacing rods, saving significant time on maintenance.

Ferobide was the material on the forefront of Sweden’s most challenging railway project – successful boring through the “impenetrable Hallandsåsen mountain” to construct two parallel tunnels with a unit length of nearly 5,500 metres and an interior diameter of about 9 metres. The tunnels are the country’s most important railway infrastructure project in 40 years. Capacity will increase from 4 to 24 trains per day, travel time between Malmö and Gothenburg will be shortened and the load capacity of freight trains will double.

None of this would be possible without Ferobide.

“We welded Ferobide plates around the cutterhead. 2km of tunnel was bored in highly abrasive granite earth, where high speed subjects the face to extreme forces. Ferobide gives significant lifetime increase of 6-7 times.”

– Skanska Vinci, Sweden Cutterhead of tunnel boring machine

- Ferobide gives life increase of 6-7 times – comparing to 500HB hardened steel

- At 5 months 500HB hardened steel is completely worn out, while Ferobide has wear life left

- Ferobide exhibits work-life of 26 months

- Ferobide reduced downtime significantly and speeded up the completion of the project

What is Ferobide exactly?

Ferobide is a weldable tungsten carbide composite material, which combines high levels of wear resistance with the ease and reliability of a weldable material.

Key Features:

- Weldable

- Resistance to sliding abrasion comparable to tungsten carbide

- Higher abrasive wear resistance than any other weldable material

When compared to other common wear resistant materials in sliding abrasion, Ferobide is:

- 15 times better than 500 HB hardened steels,

- 8-10 times better than chromium carbide plates,

- 6 times better than cast white iron,

- 4 times better than 97{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} alumina.

To learn more about Ferobide please contact Tenmat Wear.