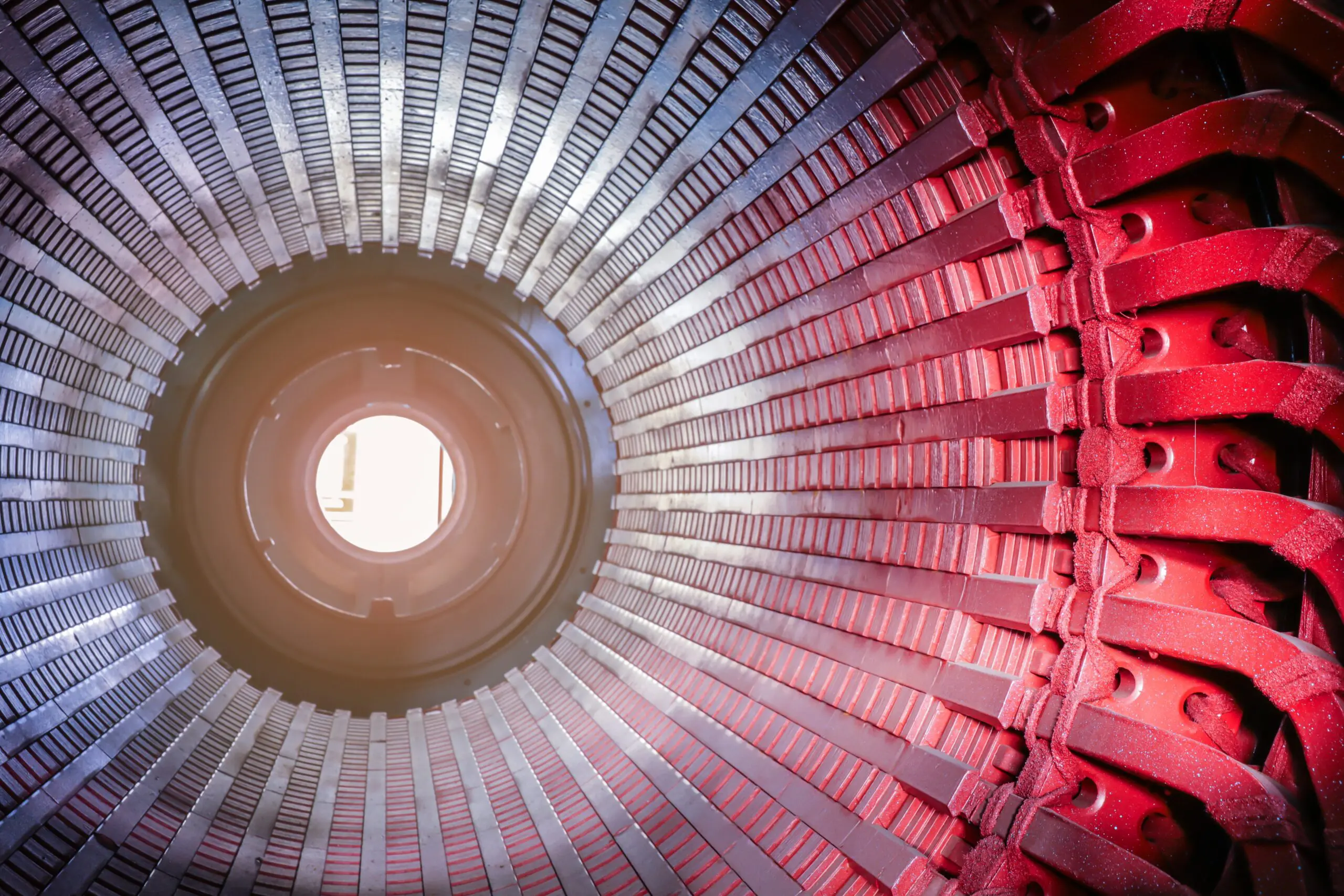

Tenmat Kevlar Fibre rollers are used to replace metal, chrome, rubber and polyurethane in the hot (aluminium) and cold rolling of metals. Our rollers have proved to be superior in leading blue-chip metal production plants across the world. They offer increased longevity with high levels of wear performance, significantly reduce unnecessary downtime and do not require any maintenance like cleaning or grinding.

Customer Benefits:

- Increase life of 7-10 times in comparison to Polyurethane

- Reduces unnecessary downtime

- Allows for more accurate predictive maintenance

- Long term savings

- Increases efficiency and reliability

- Protect surface finish of end product by not imprinting the strip

- Non marking rollers which do no pick up – nor transfer – contaminants

Feroform rollers offer a high temperature capability whilst minimizing risk of quality issues caused by poor wear performance.

Proven applications of Feroform rollers include:

- Deflector rolls,

- Tensioning/bridle rolls,

- Strip support rolls,

- Coil support rolls

- Ironing rolls,

- Conveyor rolls.

Key Features:

- Excellent stability up to 450oC

- 100{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} exonerated, non-ceramic, non-asbestos fibres

- Superb thermal insulation

- Great coefficient of friction

- Resistant to many minerals, acids, bases, solvents

- Non-marking roll

- Requires no maintenance

Please contact us HERE to enquire about all your Hot or Cold Metal Rolling needs.