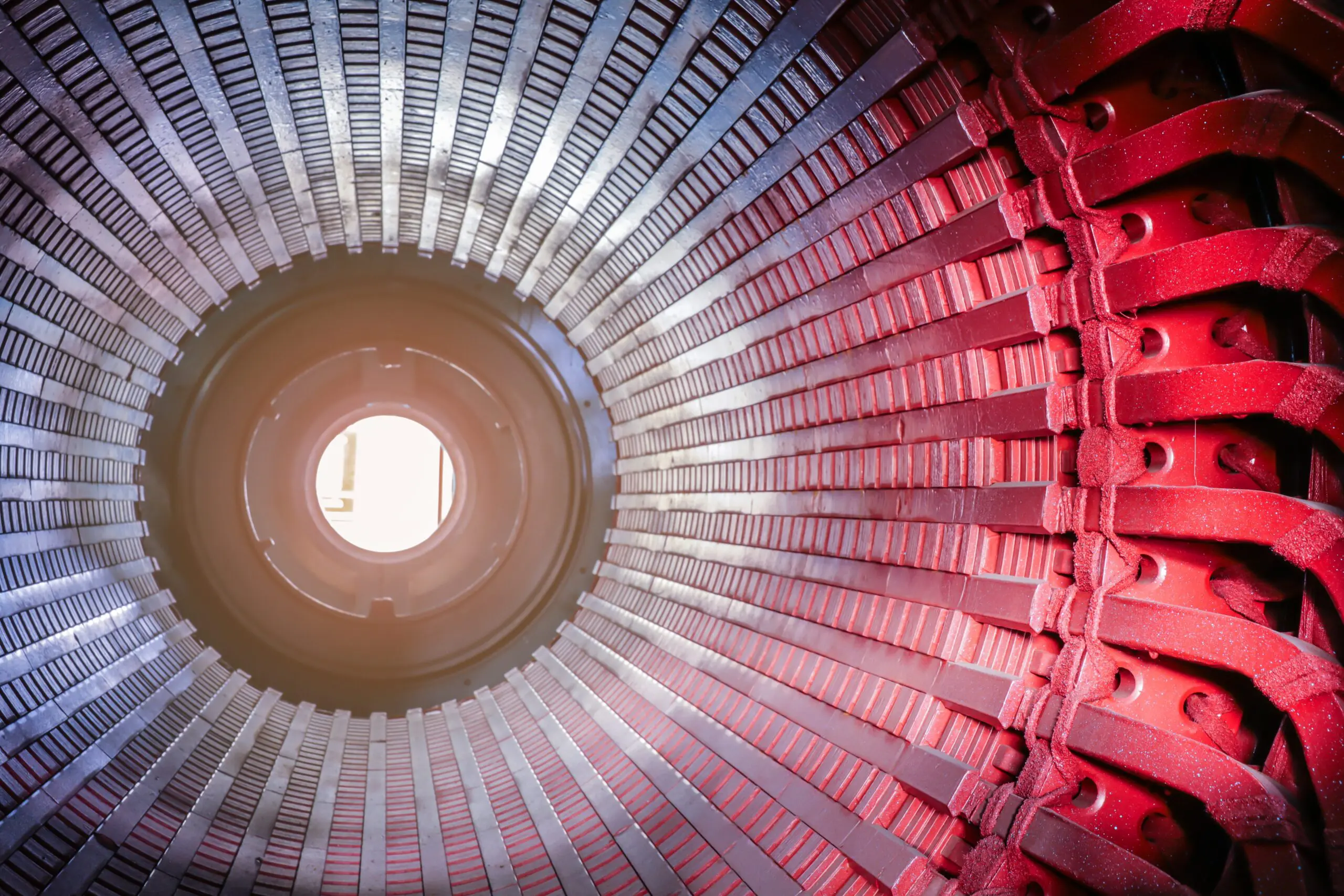

Tenmat Wear weldable tungsten carbide composite material Ferobide is the ideal solution for scroll flight protection, as it allows for direct welding to the scroll using conventional welding methods with no need for an intermediate “carrier” as conventional tungsten carbide tiles do. Since there is no need for a carrier, Ferobide tiles have a larger wear resistant surface area, protecting more of the scroll.

COMPATIBLE WITH ANY SCROLL CONFIGURATION

Ferobide is quickly installed directly to the scroll via a secure weld. This unique design allows it to be fitted to any scroll configuration. Compared to hardfacing options, welding tiles is a quicker operation.

Through its increased impact strength and weld joint bonding strength, Ferobide avoids internal damage caused by chipping and breakage.

WHAT IS FEROBIDE EXACTLY?

Ferobide is a weldable tungsten carbide composite material, which combines high levels of wear resistance with the ease and reliability of a weldable material.

Key Features:

- Weldable

- Resistance to sliding abrasion comparable to tungsten carbide

- Higher abrasive wear resistance than any other weldable material

The typical results for Ferobide in ASTM G65 tests is 3mm3 of wear, comparable to that of tungsten carbide.

When compared to other common wear resistant materials in sliding abrasion, Ferobide is:

- 15 times better than 500 HB hardened steels,

- 8-10 times better than chromium carbide plates,

- 6 times better than cast white iron,

- 4 times better than 97{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} alumina.

To learn more about Ferobide please contact the Tenmat Wear team.