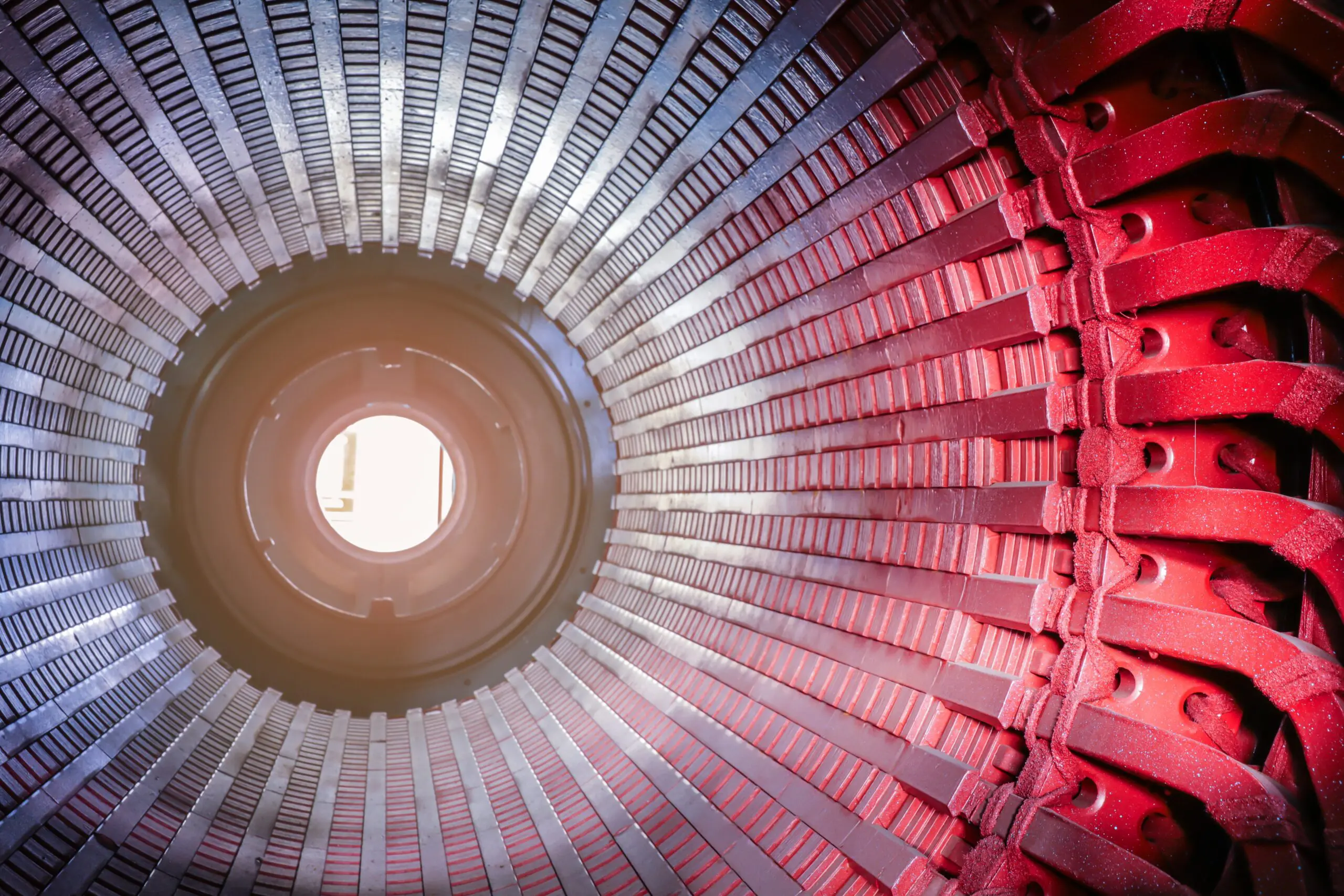

Here at Tenmat we manufacture a wide range of hot gas filter elements, which are designed to remove particulates, heavy metals, furans, nitrogen oxides, acids and dioxins from gasses at temperatures and efficiencies higher than those achievable with a conventional system. We can achieve this due to our unique non-ceramic refractory materials and inorganic bonds, which can be used in temperatures up to 1000°C. There are a number of industries where hot gas filters are common, examples include the manufacture of plastic, waste incinerator facilities as well as clinker cooling in the cement industry.

Tenmat’s high temperature filters are produced using inorganically bonded alkaline earth silicates in a way to provide more strength than any other commercially available filter, with more than 15 years of experience and numerous filters in use around the world. On top of this they are resistant to most chemicals, are thermal shock resistant and are totally incombustible through being both spark and fire proof!

In 2019 we provided a candle filter (CS1150F) to an established Strawberry Farm Nursey and Non Perennial Crop Grower who had limited space within an existing boiler house. The problem stemmed from a wood chip boiler producing emissions that were over the limit that they should be working within. After applying the Tenmat candle filter they were able to achieve atmospheric emissions of less that 3mg.

There are a number of different filter options available, the best solution will depend on what application you are using it for. If you are working within gasification and pyroliytic processes then In-line Equipment Protection (ILEP) will be the most suitable. Whereas for the Incineration of industrial and chemical waste we would recommend using an Atmospheric Pollution Control (APC). You can learn more about APC and ILEP on our website, or contact our team of experts who can advise you on which solution is best for you.