Material

FEROFORM T814

Overview

Tenmat Wear’s distribution partner in Spain – Sintemar – conducted materials tests with various end users to determine which materials were best suited for this application. Tests revealed that Ferform T814 performed the best.

Real Life Testing

A first prototype version of the system will be built in general dimensions scaled 1/3 from a real commercial structure for a 5 MW turbine. Installed in October 2020, 12 months test, at Oceanic Platform of the Canary Islands. Future tests to scale to 15 MW.

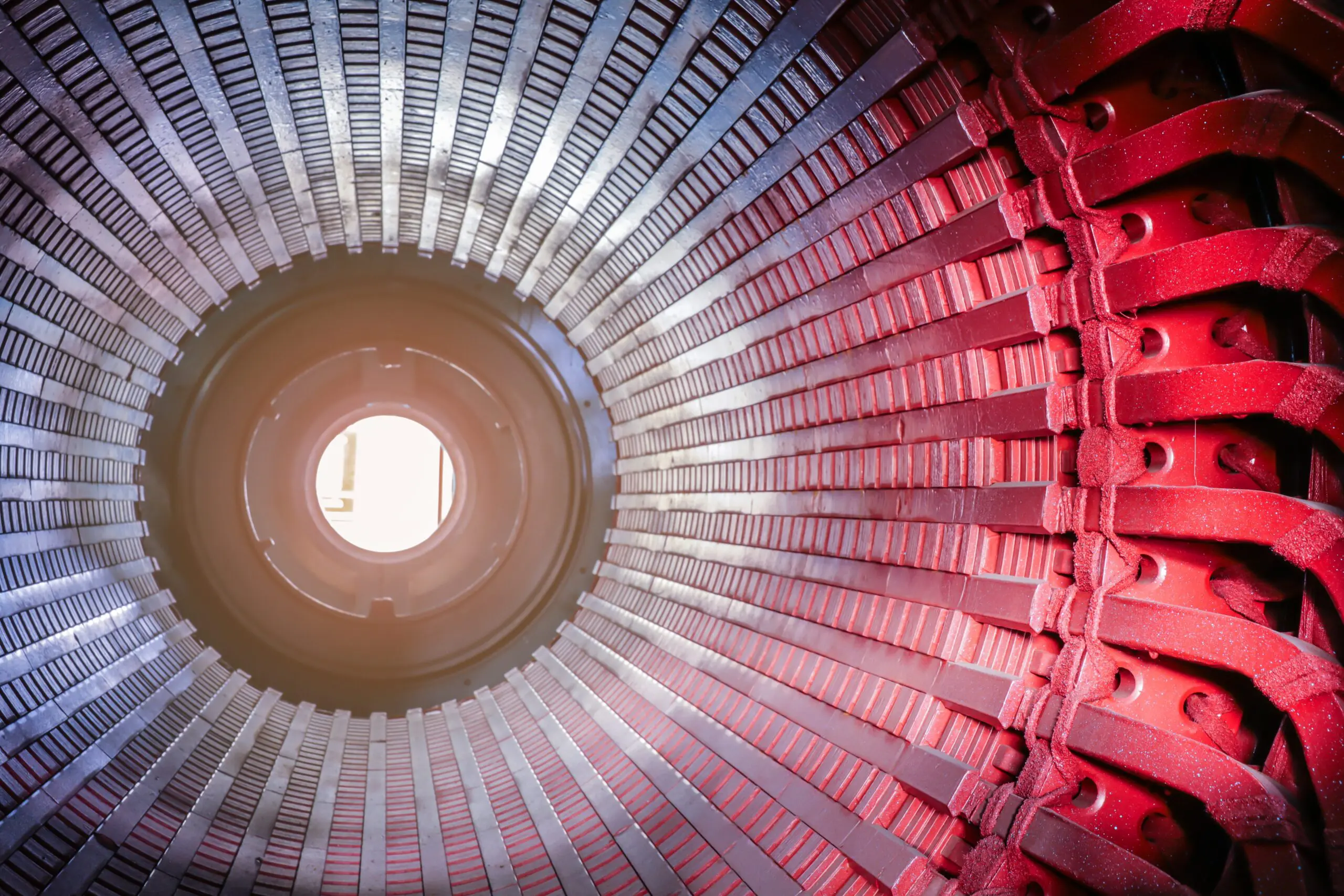

The Project

To increase carbon – free, renewable energy production by realizing huge potential of wind power in deep water areas.

The Challenge

To reduce platform weight by up to 80% and costs by 50%. Turning floating wind competitive!

Target Costs

50 Euros/ MWh

The Solution

Using Feroform T814 as heavy duty bearing materials inside the PivotBuoy design to allow superior and easy operation of rotating turbine.

Benefits of Feroform

Allows easy spinning of the turbine to follow wind directions, reducing operations costs, longer-life versus elastomers/ polyesters/other composite bearing materials, better for environment and costs because it allows a grease-free system, maintenance-free, already proven in marine sector.

Benefits of New Design

More reliable and sustainable wind energy generation with faster, more costs effective construction and installation.

Features of Feroform

- Low-friction

- Superior wear performance

- Self-lubricating

- Withstands aggressive marine working conditions.