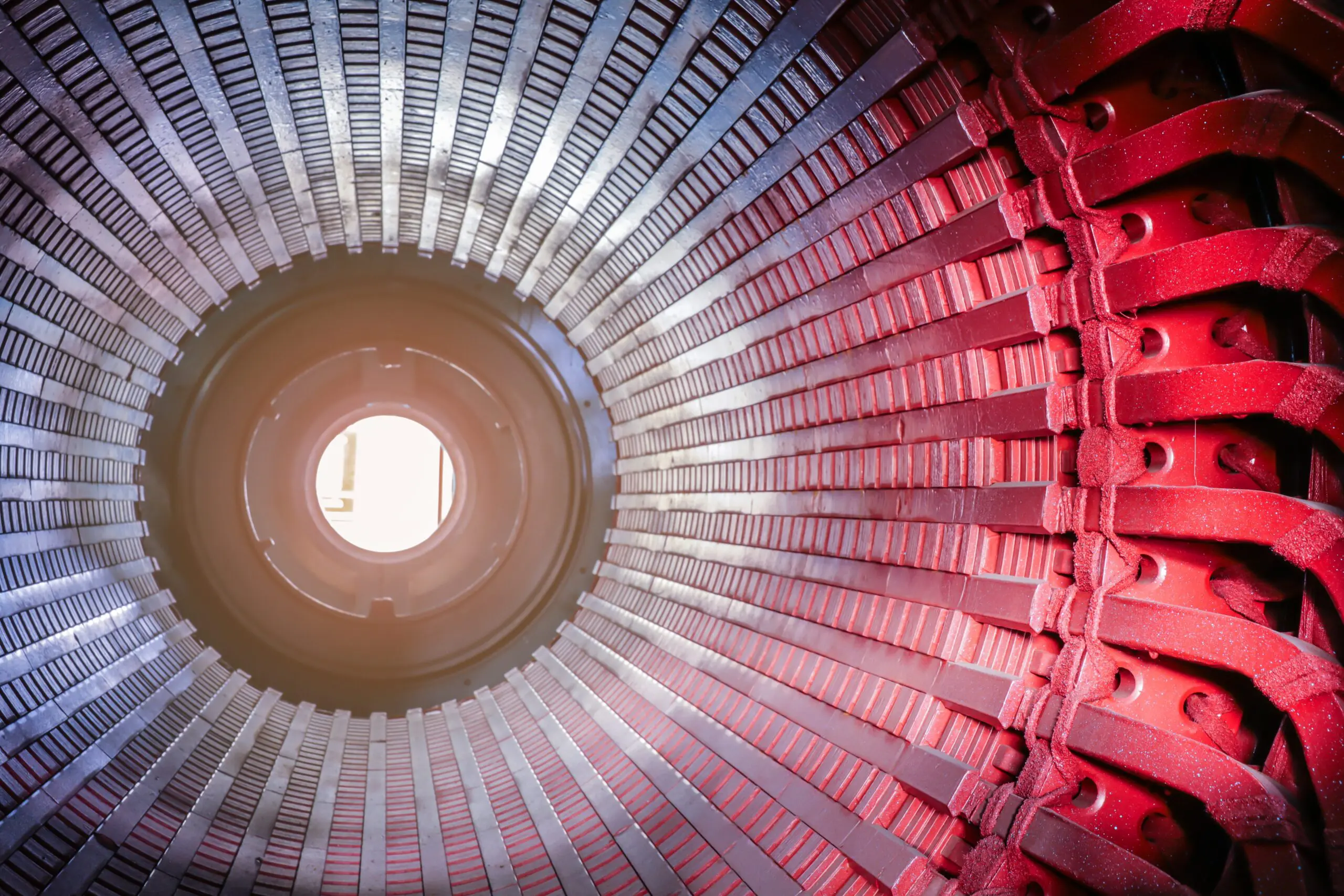

Combating mass produced, often plastic, parts in key components

A significant issue that has been challenging within the rail industry is the introduction of mass-produced, often plastic, parts being added into key components. Although this can save the manufacturer on costs, it can cause the lifetime of the products to decrease. This is because plastic materials are not reinforced and can be severely affected by changes in atmospheric moisture, heat, and high loads, which are common in the rail industry.

To ensure products do not include compromising materials it is imperative to purchase products from reputable and fully tested organisations. Tenmat’s RAILKO is already tested and trusted by household names such as Deutsche Bahn (Germany), SNCF (France) and Trenitalia (Italy) which provides peace of mind to new customers.

Tenmat have been designing, manufacturing, and supplying the railway industry with innovative composite rail components for more than 100 years which have now evolved into being the industry standard. All Tenmat products are produced using RAILKO NF21 & NF22 Grades, which have a resin bonded composite structure with added friction modifiers to give controlled friction modifiers to give a controlled friction. These grades have been developed as a high performance wearing and bearing material for many industrial applications and offer low wear and friction rates.

Our products are well respected within the industry because they have been tried and tested over many years. Tenmat are also the only company in the world who can produce genuine RAILKO and FEROFORM materials. Our wear parts and bearings are approved and specified by all the large authorities and train manufacturers for their safety critical applications, learn more on our website.

A recent industry example is from Wascosa, who use our RAILKO NF21 successfully in different subassemblies mounted onto many of their wagons and bogies.

We have also worked with GATX Rail Germany GmbH for many years, GATX use our composite materials applications due to their quality, wear and safety reasons. The self-lubricating properties and fibre reinforcements of the composite materials are a very good alternative for replacing metal and plastic wear design pivot liners from Y25 bogies.