-

What is Ferobide?

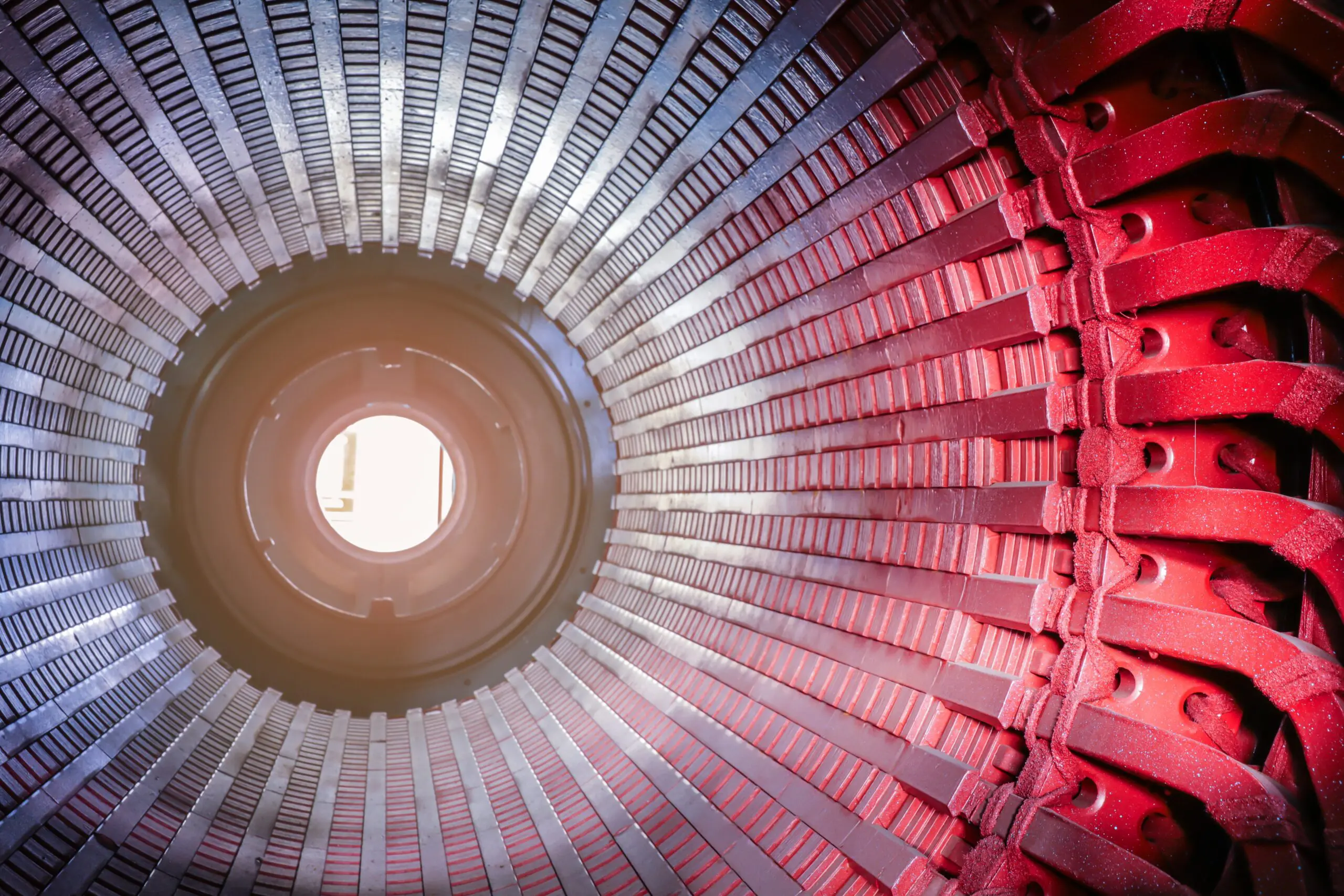

Ferobide is a weldable tungsten carbide composite wear plate. It is one of the world’s hardest weldable materials, made in the UK.

Ferobide combines high abrasion-resistance with an easy weld installation. Through years of field testing, Ferobide has been proven to save time and money.

-

How easy is it to weld Ferobide?

It is very easy and quick to weld Ferobide.

Keep heat input to a minimum, and use standard MIG / MMA methods. Clamp Ferobide in place, otherwise use on single tack per tile. For success, please see our quick welding instructions here

-

Are there any other ways to fit Ferobide?

Yes.

Welding gives best results for users. However, if large demand requires, Ferobide can be supplied stud-welded for screw installation. Please consult Tenmat Wear directly for more support.

-

What type of agricultural machinery does Ferobide work best for?

Ferobide can be used on many different machines and ground-engaging tools.

It is ideal to combat sliding wear, to prevent thinning or “washing”. Ferobide is well suited for situations where brazing is not an option and hardfacing is too slow. Typically used on seed drills, cultivators, subsoilers, ploughs, root harvesters, sugar cane harvesters, muck spreaders, buckets, mowers, augers, and scrapers.

-

Where should I weld Ferobide on my soil-engaging-part?

Behind a brazed carbide edge is a very successful use. If you place Ferobide anywhere with sliding wear, and avoid impact of leading edges, results show to be very successful.

-

Where shouldn’t I use Ferobide?

Please, avoid using standard Ferobide tiles on leading edges and points, avoiding heavy direct impact to the Ferobide. Ferobide has been specially developed for excellent sliding wear performance. Only use Ferobide on leading edges with minimal impact.

If Ferobide is the only option (where welding is the only option), please enquire directly for our leading-edge solutions. New developments in Ferobide increase impact resistance for leading edges.

Ferobide is not to be used in above ground high speed applications, e.g. toppers, hedge flails, etc.

-

How does it compare to brazed carbide or hardfacing?

Ferobide is the most durable welded material readily available on the market.

Ferobide has up to 10x performance versus hardfacing, and up to 6x versus chocky blocks. Brazed pure tungsten has a slightly better wear resistance than Ferobide. Ferobide is comparable to brazed carbide, however Ferobide is less durable. Brazed carbide is the best option for leading edges.

-

How long will Ferobide last?

When using Ferobide in the correct applications, users will achieve much greater working life of wearing metal. This will reduce downtime, and save time & money on-farm. You can see some testimonials from farms we have worked with here.

-

How can I buy Ferobide?

You can buy Ferobide online – directly from us here if you are in the UK.

We despatch UK-wide within 3 working days (as stock allows). Shipping is free on orders over £100. If you would prefer to speak to us, or are ordering from outside of the UK, please contact ferobide@tenmatwear.com 0161 872 2181

-

Do you stock it?

Yes, large Ferobide stock is available in the UK, and internationally. This guarantees quickest shipping timelines.

-

Can I buy Ferobide internationally?

Yes!

We hold stocks in several locations internationally. Please also note that delivery times might differ depending on location, check with one of our team for exact details.

-

Do other companies sell Ferobide?

Tenmat Wear is the only manufacturer of Ferobide. Ferobide is stocked by many leading farm supply companies worldwide. This is backed up by a network of agricultural experts in key locations.

Machinery OEMs are increasingly applying Ferobide to their new-build wear parts, in order to offer better cultivation performance and longer metal lifetime. Keep your eyes peeled!

-

What sizes are available?

Ferobide can be made into bespoke shapes, in terms of thickness, standard parts can be made up to 12mm thick. Or, we can manufacture tailored parts over 20mm thick. The sizes below are considered standard sizes, which we keep a stock of, ready for quick dispatch.

4 mm thick

8x40mm

15x40mm

25x60mm

40x40mm

6 mm thick

15x40mm

25x60mm

40x40mm

8mm thick

15x40mm

25x60mm

40x40mm

-

Can it be used in streamlined parts?

Thin Ferobide tiles can be used as part of min-till farming practices.

At only 4mm thick, a Ferobide tile offers excellent wear performance to keep tines and points working at depth for longer. Thanks to this performance/thickness ratio, Ferobide offers big outcome yet still reduces fuel burn versus inferior wear protection, which needs thicker parts bigger to achieve the same lifetime.