- Home

- Composite and Polymer Materials

- Sectors & Products

- Marine

- Propeller Shaft Bearings

Propeller Shaft Bearings

Tenmat Wear propeller shaft bearings provide superior wear resistance and therefore extended operational life and reduced operational costs for the marine market.

- Home

- Composite and Polymer Materials

- Sectors & Products

- Marine

- Propeller Shaft Bearings

Propeller Shaft Bearings

Tenmat propeller shaft bearings provide superior wear resistance and therefore extended operational life and reduced operational costs for the marine market.

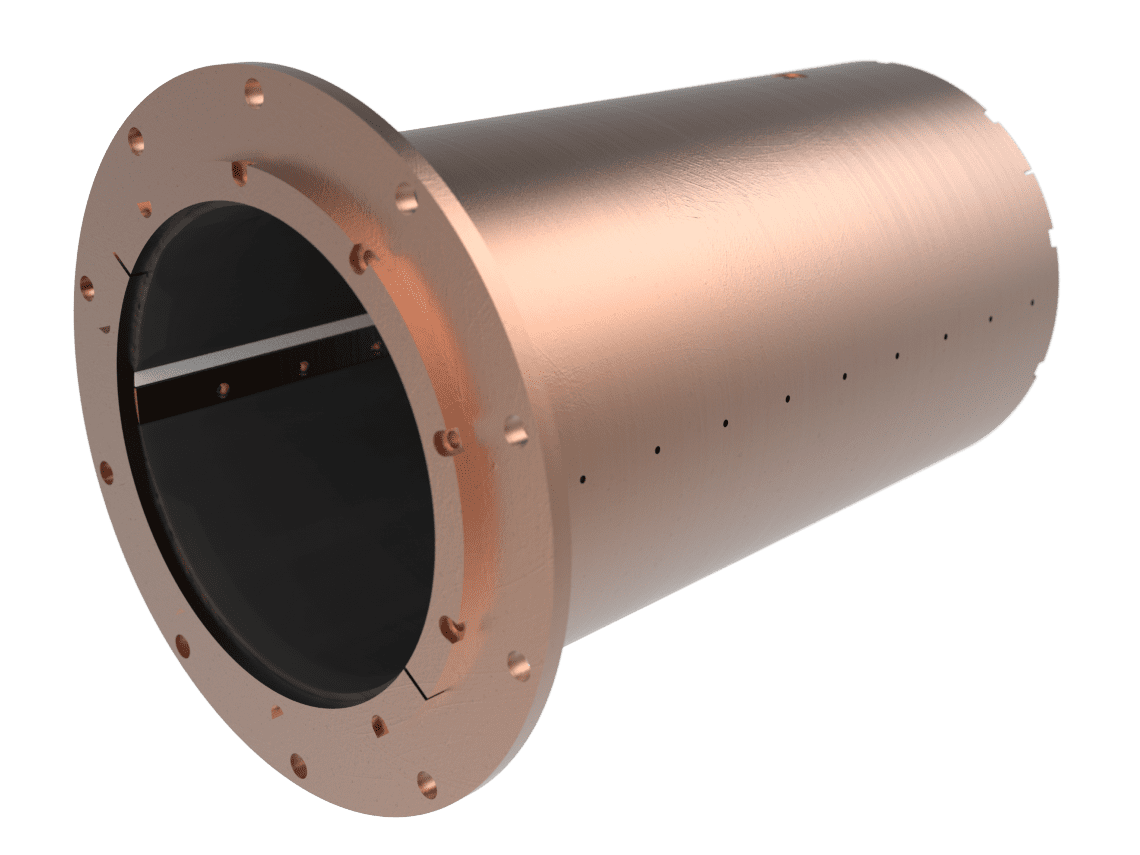

PROPELLER SHAFT BEARINGS

Market-leading durability

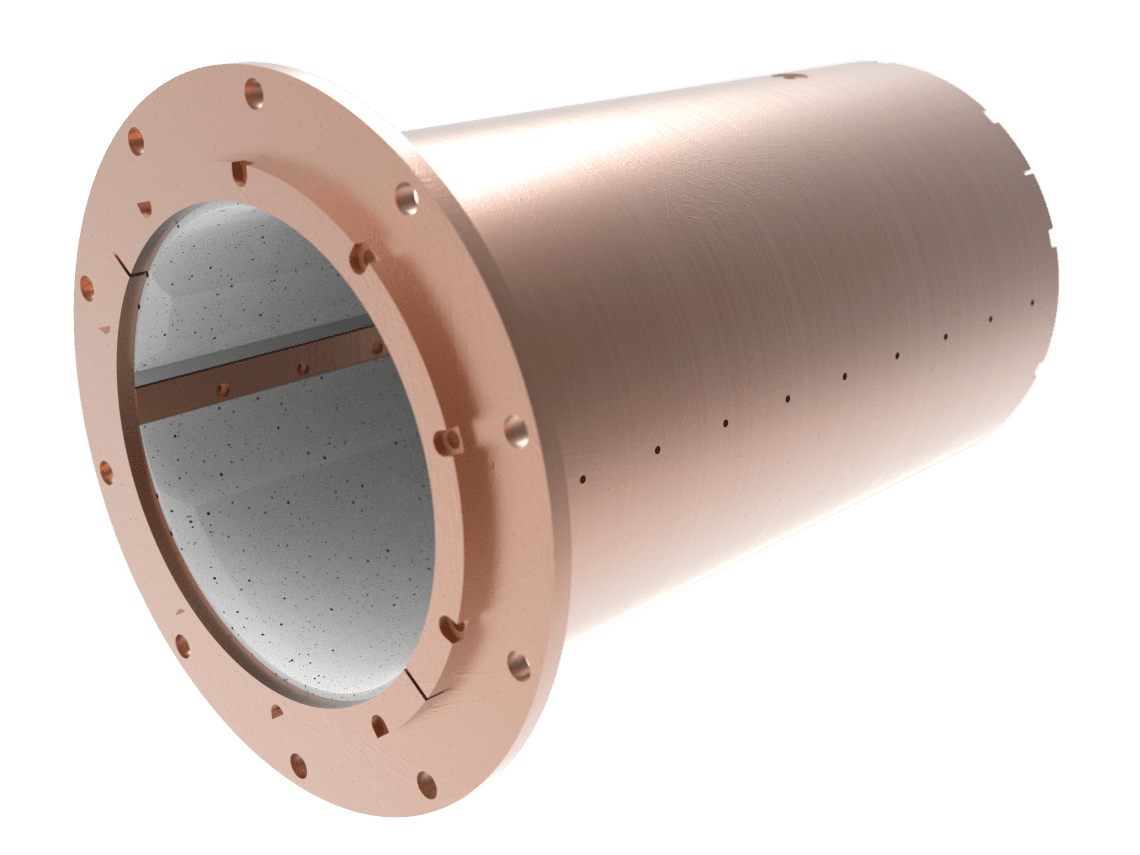

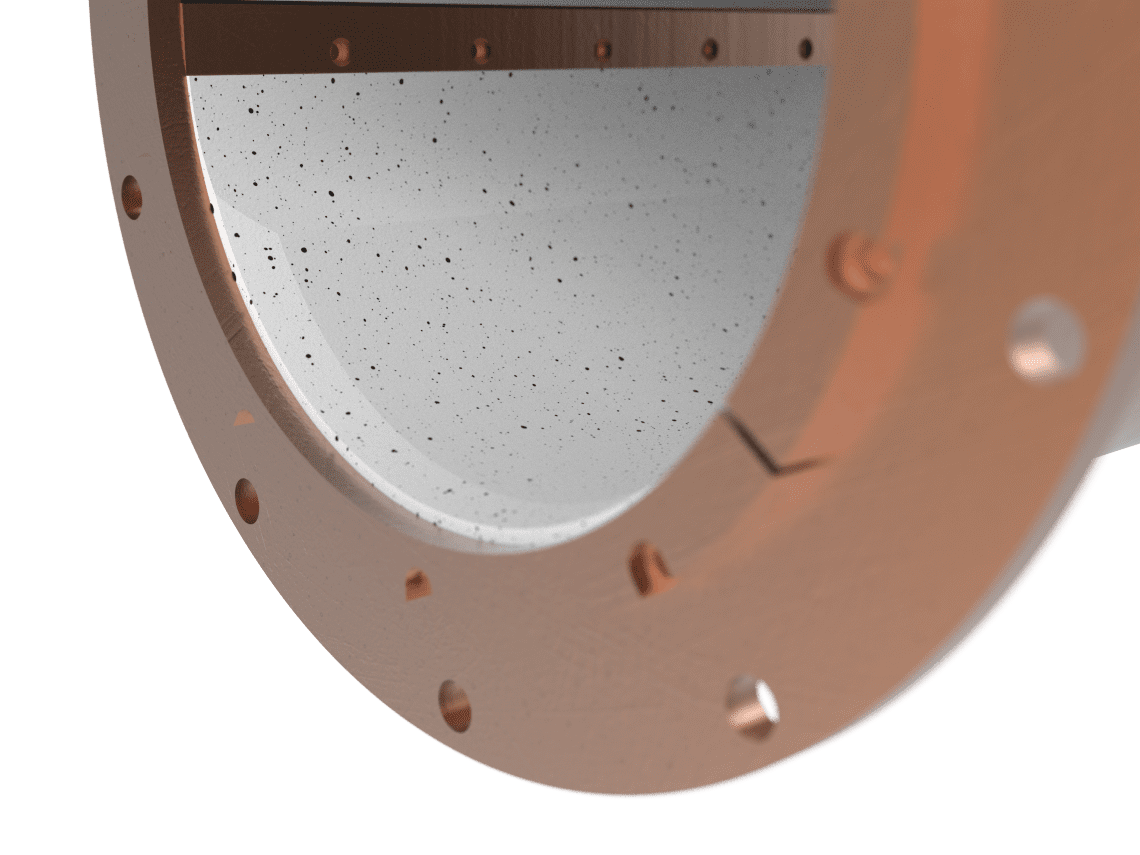

Tenmat Wear marine bearings offer market-leading durability and low noise, even in the harshest conditions without contaminating the aquatic environment. Tenmat Wear marine bearings are manufactured from fibre-reinforced thermoset material making them ideally suited to propulsion line applications such as stern tube and bracket bearings.

Durability, stability, low friction and superior wear resistance.

Offering the best combination of durability, stability, low friction and superior wear resistance to be found on the market today, Tenmat Wear Marine Bearings are fully approved by all major class societies for water and oil lubrication. They are the ideal choice for water (open flow and closed loop) and oil (mineral, synthetic and especially EAL) lubrication.

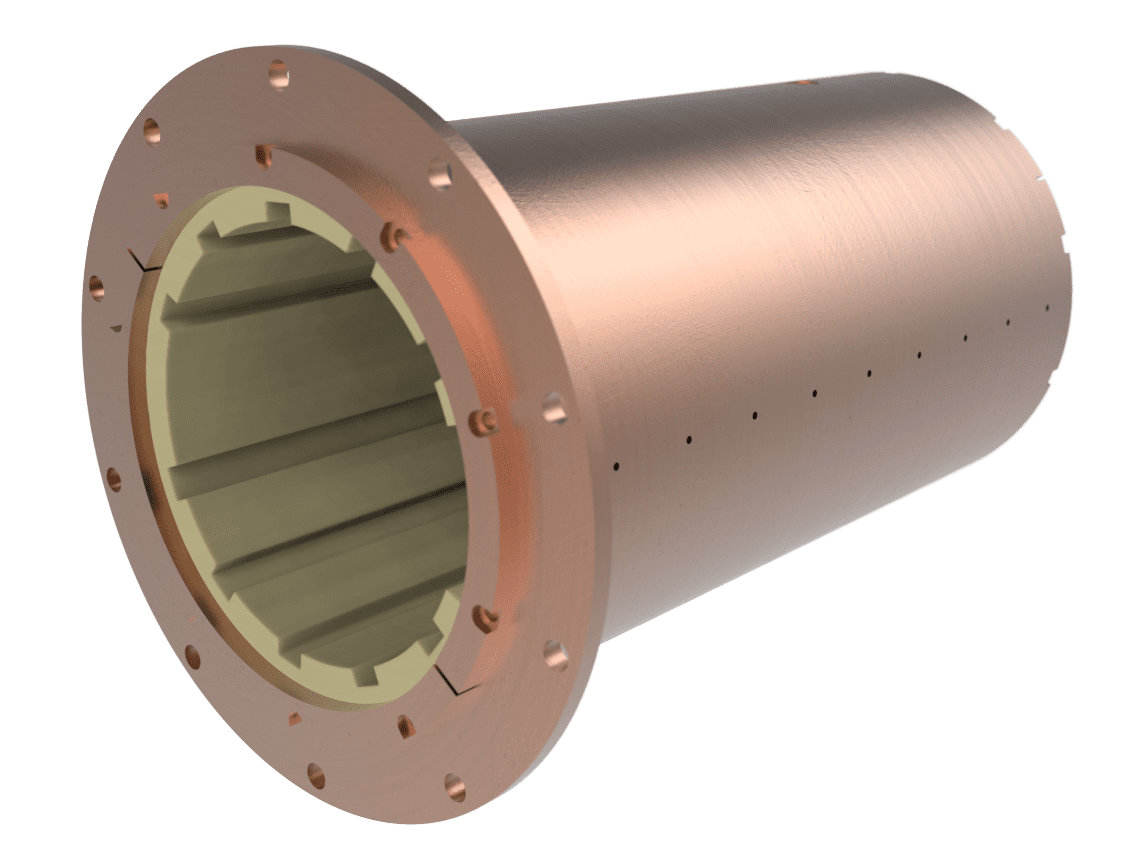

PROPELLER SHAFT BEARINGS

Used in a wide range of vessels

Tenmat Wear propeller shaft bearings do not require water treatment systems and are time-proven in open water bracket bearings used in a wide range of Naval vessels, including patrol boats, corvettes, frigates, destroyers, aircraft carriers and even submarines where the low noise signature of Tenmat Wear bearings is unrivalled.

Tenmat Wear marine bearings are easy to install and are often supplied as a complete package fitted in metallic housing

Offering longer operational life and lower operational costs. Tenmat Wear hard-wearing propeller shaft bearings are an ideal choice for Naval vessels, and commercial ships, from fishing vessels to bulkers, tankers, Aframax and Cruise Ships with over 8000 vessels being successfully fitted to date.

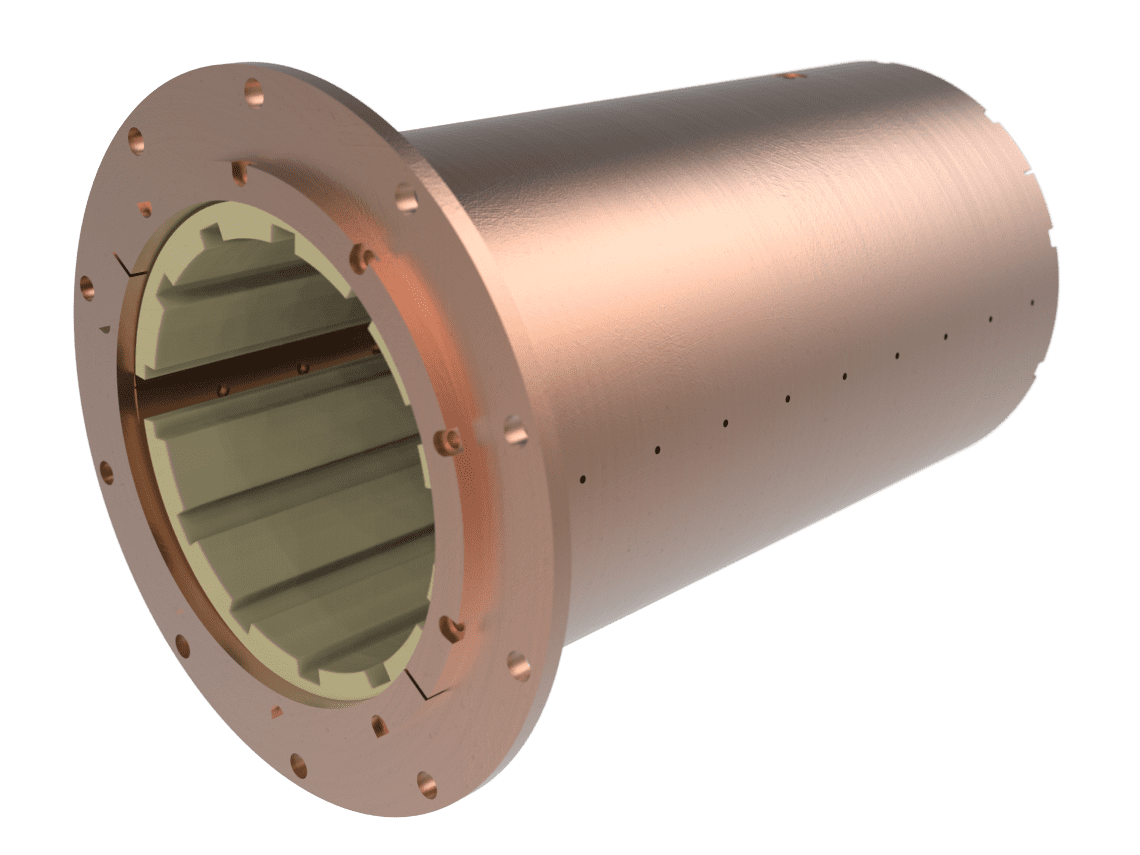

Market-leading wear performance

Resistant to abrasive waters, resulting in lower wear rates and increasing the time required between repairs.

Shaft-friendly bearing design

Optimises performance and reduces shaft scarring – and in turn, protects the bearings from further damage.

Minimal water swell and thermal expansion

Tenmat Wear supplies bearings with a very small clearance between the shaft and bearing, ensuring less shaft movement and initial bearing wear during start-up.

Accepts misalignment capable of absorbing high shock loading

Thus accommodating misalignment without damage or fracturing – meaning long-lasting bearings irrespective of the quality of shipbuilding

Stocked at strategic worldwide locations

Significant worldwide stocks of Feroform and Railko base tubes are held at strategic locations worldwide, allowing for immediate despatch to supply within tight repair schedules.

Works with all lubrication systems

Can operate with seawater, oil, or grease lubrication. Tenmat Wear composites can be used to replace failing metal bearings at short notice.

Materials

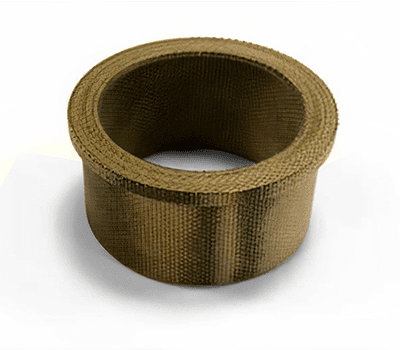

Feroform T12

Feroform T12 is a composite material made from woven fibre bonded with resin with molybdenum disulphide as a friction modifier.

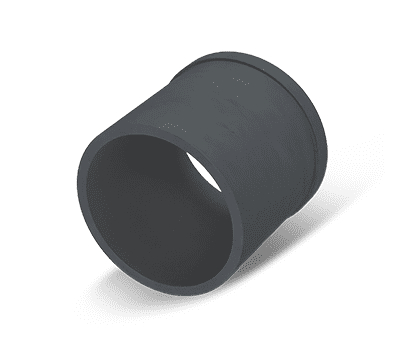

Railko NF21 & NF22

Railko NF21 and NF22 grades have a resin-bonded composite structure with added friction modifiers to control friction.