- Home

- Composite and Polymer Materials

- Sectors & Products

- Renewable Energies

Renewable energy composites

High-performance products to keep the power on

Composites for renewable energy

Reliable products for renewable energy

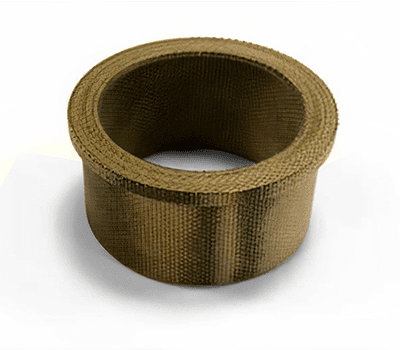

Ferofrom T814 bearings are used in a variety of applications for renewable power such as main turbine shaft bearings and actuation linkages. For wave and tidal power applications, the ability to work well in an aggressive seawater environment is a key reason why designers choose Feroform T814.

- Use in both dry and wet conditions

- Low friction coefficient

- High compressive strength

- Low water swell

- Self-lubricating

Applications

Other applications include sliding pads and bushes in wind turbines.

Materials

Feroform T814

Composite material made from woven fibre bonded with resin with PTFE as a friction modifier.

High-performance composites for renewable energy

In the rapidly expanding field of renewable energy, the reliability and efficiency of components are paramount. Tenmat’s advanced composite materials, particularly Feroform T814, are proving indispensable. Designed for critical applications within the renewable energy sector, these composites are utilised in main turbine shaft bearings and actuation linkages, essential for both wind and hydroelectric power generation. The superior durability and self-lubricating properties of Feroform T814 make it especially suited for operation in the harsh, corrosive conditions of seawater environments found in wave and tidal energy systems. This ensures optimal performance with minimal maintenance, essential for the demanding conditions of renewable energy applications. Whether operating in dry or wet conditions, Feroform T814’s low friction coefficient and high compressive strength minimise wear and extend the service life of energy systems, helping to keep the power flowing efficiently and reliably.